Moisture sensors for accurate dry‑out measurements of screed

Place the sensor on your floor. Pour the screed. Scan and monitor the relative humidity of your screed instantly in the cloud. Know when your screed is dry without relying on destructive drilling during your dry-out process. And prove your quality for years.

The old way

The screed must be dry to continue construction. But sometimes, it doesn't dry on time. The project stops. On top of all your responsibilities, panic sets in. You use heaters and fans to dry out the screed last minute. And you have paid for multiple expensive drilling tests before getting a certificate that your screed is finally dry

The InviSense way

Place the sensor in your screed. The sensor glues to the floor and is automatically in the middle of the screed. Use the included scanner to get a moisture reading any time you want. Now, you always know the relative humidity of your screed. Save money and time with zero destructive drillings. See the journey from wet to dry in the cloud service.

Eliminate guesswork and make your screed drying predictable and simple

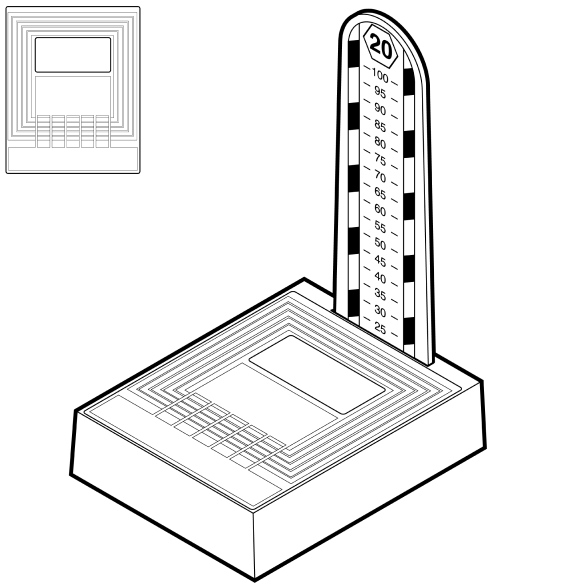

The ScreedSensor

Take control of screed drying with our screed sensor. It's simple: attach it to the floor before the screed application, scan it weekly, and track drying progress in the cloud. You'll know exactly when it's dry and detect any deviations promptly. This enables swift interventions, which help you keep your crucial construction milestones and schedule.

Key features

- Smart moisture tracking for enhanced drying insights

- +40 years durability with reliable adhesion for quick setup

- Scan frequency based on actual dry-out levels

- Built-in screed depth measurement

- Non-destructive to the screed

See the dry-out curve

The moisture sensors give you the power to measure moisture in all screed types. Place the sensor, and pour out the screed. Scan and see the dry-out curve from over 100% relative humidity in the cloud. Detect deviations early and get projects that run smoother. And on time.

Know the screed depth

Measure the screed to the last millimeter. The sensors include a measuring stick. Place the sensor in the screed and see the screed depth instantly. This simple helper empowers you to plan your screed distribution accurately to save money on material costs.

Monitor in different screed thickness

Your screed needs constantly change. Get measurability in all screed thicknesses over 30 millimeters. The sensors work in different depths and continuously empower you to measure moisture across your construction. Your project planning just got simpler.

Ongoing moisture assessment

Receive immediate and ongoing updates about all your screed drying processes. All sensor data is collected automatically for each project. Simply scan using the provided scanner. The app shows you the exact moisture levels for all sensors.

Non-destructive sampling

Get moisture readings any time without destructive drilling. Once the sensor is in your screed, you can access relative humidity readings. Order one final drilling test for certification when the sensors show an acceptable moisture percentage.

Incredibly long-lasting

Prove your quality from the start. Protect yourself from complaints and construction mishaps with sensors that prove your excellence. The sensors last over 40 years, giving you time to prove that your screed dry out was always correct.

Pay once, use forever

Forget expensive moisture tests. Pay once and use forever. The affordability lets you invest in more sensors for better planning and quality control. Use the sensors in problematic areas, like bathrooms or rooms where you want moisture insights.

Questions? Answers.

We know a few things about moisture control, the construction industry, and how construction managers can avoid project delays. We're to help. Get in touch.

When do I install the sensor?

When do I install the sensor?

Prime the floor first, then install the sensor. Installing the ScreedSensor after priming gives you the screed's most accurate relative humidity measurements.

What happens if I don’t register the temperature?

What happens if I don’t register the temperature?

Nothing. The ScreedSensor will still give you relative humidity readings in your screed. However, if there's a problem, a common question is, "What was the temperature?" That's because temperature influences the screed's moisture content. Knowing the temperature can help explain deviations in your drying process.

What type of ScreedSensor is right for my type of screed?

What type of ScreedSensor is right for my type of screed?

The type of ScreedSensor you need depends on the screed thickness you want to use. Place the sensor 30-50% down in the screed for the best moisture measurements.

If you use a 40 mm thick screed, use the 20-sensor. For a 50 mm thick screed, use the 35-sensor.

Remember to register the final screed depth. If the screed depth is different than you planned, our algorithms compensate for the deviations for the highest accuracy.

Why do I need to share the type of screed I use?

Why do I need to share the type of screed I use?

Screeds are different. And to give you the best relative humidity measurements, we have tested a wide range of screeds. By telling us your type of screed and thickness, our algorithms help give you the best results on each type of screed you use.

Discover a construction project booster

Sensors make moisture easy to control. See how the InviSense sensors can simplify your decision-making, cut project time, and make your screed drying process a non-issue. Contact us, and one of our experts will be on the other side to help you.